Understanding how to identify different metals is essential for anyone interested in recycling or reselling materials, and that’s where a scrap metal identification guide comes in. Knowing whether a piece of metal is copper, aluminium, brass, or steel can make a big difference in both environmental impact and financial return. For businesses and households looking to sell scrap metal in Melbourne, being able to accurately identify and sort materials ensures higher payouts and more efficient recycling. Every metal has its own characteristics, from weight and colour to magnetic properties, and learning to recognise these differences can turn unwanted items into valuable resources. Whether you’re decluttering a worksite, running a recycling operation, or simply curious about sustainable living, mastering metal identification is a useful and rewarding skill. By sorting smarter, you’re not only saving resources but also contributing to Australia’s growing circular economy.

Understanding Scrap Metal and Its Value

Scrap metal plays a vital role in Australia’s recycling industry, turning discarded materials into reusable resources that support sustainability and the circular economy. To identify scrap metal effectively, it’s essential to understand the two main categories — ferrous metals and non-ferrous metals. Ferrous metals, such as steel and iron, contain magnetic properties, while non-ferrous metals like copper, aluminium, brass, and stainless steel do not. Recognising these differences is key to separating metals efficiently and maximising returns when you sell scrap metal.

Proper identification not only helps recyclers process materials correctly but also ensures compliance with scrap metal laws in Victoria and other regions. Common tools like magnets, files, and colour charts make it easier to distinguish one type of metal from another. For instance, copper has a reddish-brown hue, while aluminium is light and silver in appearance. By improving your scrap sorting skills, you can reduce waste, enhance recycling outcomes, and increase the value of your metal collection. Understanding these characteristics empowers individuals, businesses, and tradespeople to contribute to a cleaner, greener future while reaping financial benefits.

Common Types of Scrap Metal and How to Identify Them

Recognising different types of scrap metal is essential for anyone involved in metal recycling, from tradespeople and demolition workers to homeowners looking to sell scrap metal responsibly. The most common metals found in the recycling stream include aluminium, copper, brass, stainless steel, iron, and steel — each with distinct properties and visual cues that make identification easier.

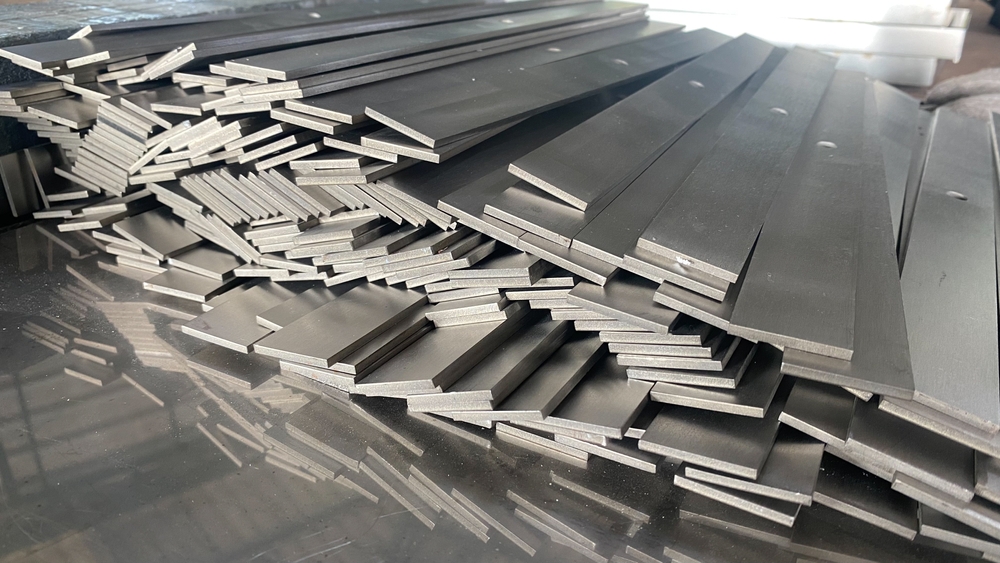

Aluminium is lightweight, silvery, and resistant to rust, making it a popular choice in cans, window frames, and automotive parts. Copper, known for its reddish-brown colour, is highly conductive and valuable, often sourced from electrical wiring and plumbing pipes. Brass, a yellow-gold alloy of copper and zinc, is commonly found in fixtures, taps, and decorative fittings. Stainless steel is non-magnetic and corrosion-resistant, used widely in kitchen equipment and machinery. Meanwhile, iron and steel are magnetic and heavier, typically recovered from construction materials and appliances.

A simple magnet test can help distinguish between ferrous and non-ferrous metals. Ferrous metals will attract magnets, while non-ferrous ones will not. Beyond this, checking the metal’s weight, colour, and texture can reveal its identity. Developing the ability to quickly recognise metals ensures accurate sorting, better recycling outcomes, and higher payouts at scrap metal yards.

How to Identify Scrap Metals

Identifying scrap metals accurately is a crucial skill for recyclers, tradespeople, and anyone looking to sell scrap metal for profit. Each metal type has unique characteristics, from colour and weight to magnetism and texture.

Visual Identification

Visual inspection is often the first step in scrap metal identification. Metals like copper have a reddish-brown hue, while brass appears yellowish-gold. Aluminium is silvery and lightweight, whereas stainless steel has a polished finish that resists rust. Taking note of colour changes, corrosion, or patterns can often distinguish between alloys and pure metals. For instance, tarnished brass will darken over time, while aluminium stays bright and smooth.

The Magnet Test

The magnet test is a quick and effective way to separate ferrous metals from non-ferrous metals. Simply place a magnet near your scrap — if it sticks, it’s likely iron or steel. Non-ferrous metals, such as copper, aluminium, brass, and stainless steel, will not attract magnets. This test is commonly used in scrap metal recycling centres to streamline sorting and improve recycling efficiency.

Weight, Sound and Spark Tests

The weight, sound, and spark tests offer additional clues. Heavier metals like steel and iron produce a dull “clunk” when struck, while lighter metals like aluminium sound higher-pitched. When ground on a wheel, ferrous metals emit bright sparks, while non-ferrous metals produce few or none. Combining these tests helps recyclers identify materials accurately, ensuring optimal sorting and environmentally responsible metal recovery.

Common Types of Scrap Metal and Their Value

Understanding the types of scrap metal and their respective values can help recyclers, tradespeople, and households make informed decisions when sorting and selling materials. The two main categories are ferrous metals and non-ferrous metals, each with unique properties and market worth.

Ferrous metals, such as steel and iron, contain magnetic properties and are among the most commonly recycled materials in Australia. While their scrap value per kilogram is relatively low, they are widely available and contribute significantly to large-scale recycling efforts, especially in construction and manufacturing sectors.

Non-ferrous metals, including copper, brass, aluminium, stainless steel, and lead, are far more valuable due to their resistance to corrosion and high conductivity. For instance, copper is one of the most sought-after materials in the scrap metal recycling industry, often found in wiring, pipes, and electrical components.

Accurate scrap metal identification allows sellers to separate metals by type before visiting a scrap yard, ensuring they receive fair pricing. With fluctuating scrap metal prices, understanding the material composition and market demand plays a major role in maximising returns.

Tools and Techniques for Identifying Scrap Metal

Recognising and categorising different types of scrap metal is essential for anyone looking to sell scrap metal effectively or improve recycling efficiency. Using the right tools and techniques ensures metals are identified quickly and accurately, helping recyclers achieve better value and maintain compliance with industry standards.

One of the simplest tools for metal identification is a magnet. Ferrous metals, like steel and iron, are magnetic, while non-ferrous metals such as aluminium, brass, and copper are not. This basic test can immediately help separate metals into key groups. A file test is another useful technique, allowing recyclers to observe the colour or texture beneath a metal’s surface coating to determine its composition.

Safety Considerations When Identifying Scrap Metal

Safety is a crucial aspect of scrap metal identification, especially for those handling sharp, heavy, or contaminated materials. Proper precautions reduce the risk of injury and ensure compliance with workplace safety standards in Australia.

When sorting or testing metals, it’s important to wear protective gloves, safety goggles, and sturdy footwear. These prevent cuts from jagged edges and protect against sparks during grinding or spark tests. Clothing should cover exposed skin, and long hair should be tied back to avoid entanglement in machinery.

Handling tools such as grinders, files, and magnets must be done carefully, and work areas should be well-lit and organised. Additionally, materials like lead, batteries, or coated wires require careful handling to prevent exposure to hazardous substances.

By adopting proper safety measures, individuals and businesses can identify ferrous and non-ferrous metals confidently, improving the quality of scrap metal recycling while maintaining a safe environment. Prioritising safety protects workers and supports responsible metal recovery practices across Melbourne and beyond.

Environmental and Economic Benefits of Accurate Scrap Metal Identification

Proper scrap metal identification has significant environmental and economic advantages. By accurately sorting ferrous and non-ferrous metals, recyclers reduce contamination, improve processing efficiency, and ensure that more materials are reused rather than ending up in landfill. This helps lower greenhouse gas emissions and conserves natural resources, contributing to a sustainable circular economy in Australia.

Accurate identification also maximises financial returns for individuals and businesses. Clean, correctly sorted metals such as copper, aluminium, and brass command higher prices at scrap metal yards. Even small differences in metal purity or grading can impact overall revenue, making proper identification a key step for anyone looking to sell scrap metal profitably.

Moreover, efficient sorting reduces the energy required to process metals, further lowering environmental impact. By combining economic benefits with responsible recycling practices, individuals and companies play an active role in promoting sustainability while supporting the metal recovery industry in Melbourne and across Australia.

Are You Ready to Sell Scrap Metal?

Look no further than Metal Men Recycling. We make selling scrap metal an easy and straightforward process and pride ourselves on exceptional customer service.

Get in touch with us by calling 03 5941 6677 or by filling in our online contact form and we will get back to you.

Frequently Asked Questions (FAQ)

What is scrap metal identification?

Scrap metal identification is the process of recognising different types of metals, such as aluminium, copper, brass, steel, and stainless steel, to sort and recycle them effectively.

Why is it important to identify scrap metal accurately?

Accurate identification ensures higher resale value, reduces contamination, and supports environmentally responsible recycling practices.

How can I tell ferrous metals from non-ferrous metals?

Ferrous metals are magnetic and contain iron, while non-ferrous metals like aluminium, copper, and brass are non-magnetic and often more valuable.

Can I safely identify scrap metal at home?

Yes, but always use protective gloves, goggles, and proper handling techniques when performing tests or cutting metals.

How does identifying scrap metal benefit the environment?

Correct identification reduces landfill waste, conserves natural resources, lowers energy use, and supports a sustainable circular economy.